Easiest House Types Comparison Tool

Prefabricated

Factory-built modules delivered and assembled on-site

Modular

Compliant factory sections stacked on-site

Tiny House

Compact living spaces under 400 sq ft

Pole-Barn

Timber posts support structure with minimal foundation

Container Home

Repurposed steel shipping containers

Earthbag

Soil-filled bags forming load-bearing walls

Quick Comparison Table

| House Type | Build Time | Avg Cost (USD) | Skill Required | Permit Complexity |

|---|

Detailed Features

Select a house type above to see detailed features and considerations.

Ever wondered which kind of house you can get up and running with the least hassle? The good news is that you don't need a massive crew or a multi‑year timeline to put a roof over your head. Below is a straight‑talk rundown of the house styles that cut through the red tape, keep costs low, and let you move in faster than you’d expect.

Why some house types are a breeze to build

Three factors usually decide how easy a house is to assemble: prefabrication level, foundation simplicity, and regulatory load. When most components arrive on site ready to snap together, you skip on‑site framing, cutting both labor and weather delays. A shallow foundation - like concrete piers or a slab - reduces excavation work. Finally, designs that fit standard zoning codes avoid lengthy permit battles.

Prefabricated house - the ultimate shortcut

Prefabricated house is a home whose walls, floors and roof sections are manufactured off‑site and delivered as complete modules. Because the bulk of the structure is built in a factory, quality control is high and waste is low. Most builders can erect a typical 1,500‑sq‑ft model in 7‑10 days once the foundation is set. The process usually follows a simple three‑step timeline: (1) lay a concrete slab, (2) crane the modules into place, (3) connect utilities and finish interior trim.

Modular home - the flexible cousin of prefabs

Modular home refers to factory‑built sections that comply with local building codes and are stacked on‑site. Unlike traditional prefabs that often use a single‑piece design, modular homes let you mix and match sections - add a bedroom, expand a porch - without starting from scratch. The average build time for a 2‑bedroom modular home sits around 4‑6 weeks, including site prep. Because each module is engineered for transport, you avoid the heavy lifting that a stick‑built frame demands.

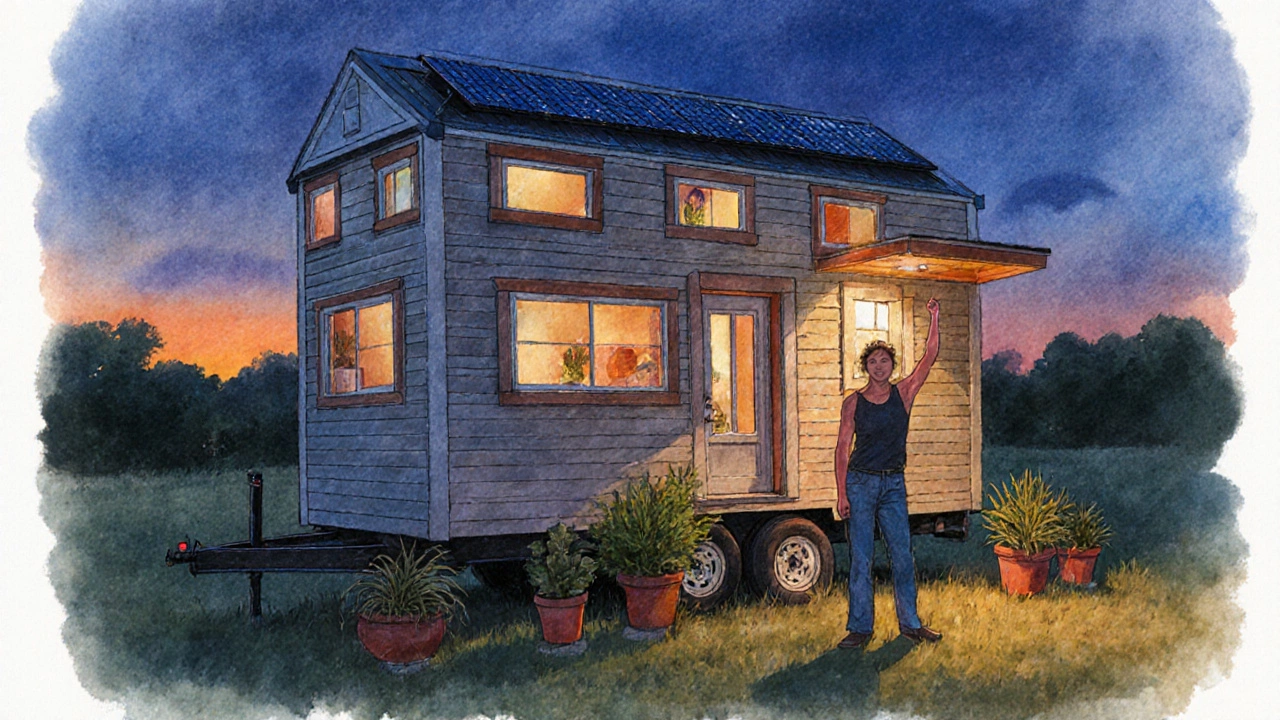

Tiny house - the minimalist sprint

Tiny house is a compact dwelling, typically under 400sqft, that can be built on a trailer or a small foundation. Its charm lies in speed: an experienced DIYer can complete a trailer‑based tiny house in 2‑4 weeks using a combination of plywood framing and off‑the‑shelf cabinetry. Permitting is often simple because the structure falls into accessory dwelling unit (ADU) categories in many jurisdictions. The trade‑off is limited space, but clever storage solutions make it livable for singles or couples.

Pole‑barn home - the rustic quick‑build

Pole‑barn home is a building that uses timber posts set directly into the ground to support walls and roof. This method eliminates the need for a full concrete foundation, slashing excavation time to a single day. Once the poles are in place, you attach metal or wood wall panels and a roof truss system. Skilled hobbyists can finish a 1,200‑sq‑ft pole‑barn in under a month, making it a favorite for rural or semi‑rural projects where building permits are more relaxed.

Shipping container home - the industrial shortcut

Shipping container home repurposes standard steel cargo containers as structural walls and roof sections. Because the container is already a sealed, load‑bearing box, you skip framing entirely. Modifications - cutting windows, adding insulation, installing doors - can be done in a weekend with basic metalworking tools. The biggest speed win comes from the fact that the core structure arrives on site ready to stack, so a simple 2‑container layout can be habitable in 3‑5 weeks.

Earthbag house - the low‑tech, low‑cost option

Earthbag house uses polypropylene bags filled with local soil to form load‑bearing walls. Construction is labor‑intensive but requires no heavy machinery or specialized skills. After piling the bags, you tamp them down, apply barbed wire for reinforcement, and finish with plaster. A 1,000‑sq‑ft earthbag house can be completed in 6‑8 weeks by a small crew, and because the materials are often sourced on‑site, the overall cost stays very low.

How to pick the right easy‑build home for you

Consider three personal criteria before committing:

- Budget ceiling - Prefabs and modular homes have higher upfront material costs but save on labor. Tiny houses and earthbag homes win on raw material price.

- Land characteristics - If your plot is flat and accessible, a pole‑barn or container home works well. Sloped or flood‑prone sites may favor raised tiny houses on trailers.

- Skill level & time - DIY enthusiasts enjoy the hands‑on process of tiny or earthbag homes. If you prefer a near‑plug‑and‑play experience, choose prefabricated or modular options.

Quick comparison of the easiest house types

| House type | Typical build time* | Average cost (USD) | Skill required | Permit complexity |

|---|---|---|---|---|

| Prefabricated house | 7‑10 days | $120‑$180 per sqft | Low | Moderate |

| Modular home | 4‑6 weeks | $100‑$150 per sqft | Low‑Medium | Moderate |

| Tiny house | 2‑4 weeks | $60‑$90 per sqft | Medium | Low‑Medium |

| Pole‑barn home | 3‑5 weeks | $80‑$120 per sqft | Low | Low |

| Shipping container home | 3‑5 weeks | $70‑$110 per sqft | Medium | Low‑Medium |

| Earthbag house | 6‑8 weeks | $40‑$70 per sqft | High | Low |

*Times assume a prepared foundation or ground‑level site and a small crew of 2‑3 people.

Common pitfalls and how to avoid them

Even the "easiest" builds can trip up if you ignore these details:

- Skipping soil tests - Poor ground conditions can ruin a slab or pole‑barn. A simple percolation test saves weeks of re‑work.

- Underestimating utility connections - Water, electricity and sewage often take longer than the structure itself. Coordinate with local utilities early.

- Ignoring local zoning - Some municipalities cap building height or require minimum square footage. Double‑check before ordering modules.

- Over‑customizing - Adding extra windows or a complex roof can delay a prefabricated project. Stick to the approved plan for speed.

Next steps: turning the idea into a reality

Ready to pick a path? Here’s a quick roadmap:

- Define your budget ceiling and land size.

- Check local zoning for the house type you favor.

- Get quotes from at least two reputable builders or manufacturers.

- Secure a simple foundation - a concrete slab works for most easy builds.

- Schedule site delivery and set a clear timeline with the builder.

Follow these steps and you’ll have a functional home faster than you thought possible. The easiest house to build isn’t a myth - it’s a matter of matching the right design to your situation.

Frequently Asked Questions

Can I build a prefabricated house myself?

Most prefabricated houses require a professional crew for the crane lift and final connections, but a savvy DIYer can handle site prep, foundation work and interior finishes. Working with the manufacturer on a clear installation plan is key.

Do tiny houses on trailers need a building permit?

It depends on local regulations. Many jurisdictions treat trailer‑based tiny homes as recreational vehicles, which means a standard RV registration suffices. If you place it on a permanent foundation, you’ll likely need a residential building permit.

How durable is a shipping container home?

Steel containers are designed to withstand harsh ocean conditions, so they’re structurally sound for residential use. Proper insulation and corrosion‑resistant paints extend their lifespan to 50years or more.

What are the insulation options for pole‑barn homes?

Spray foam, rigid foam board, or insulated metal panels work well. The choice hinges on climate: spray foam excels in extreme cold, while foam board is cost‑effective for moderate zones.

Is an earthbag house legal in most places?

Because earthbag construction is non‑traditional, some municipalities require a special variance. However, many rural areas accept it as an alternative natural building method, especially if you provide engineering calculations.